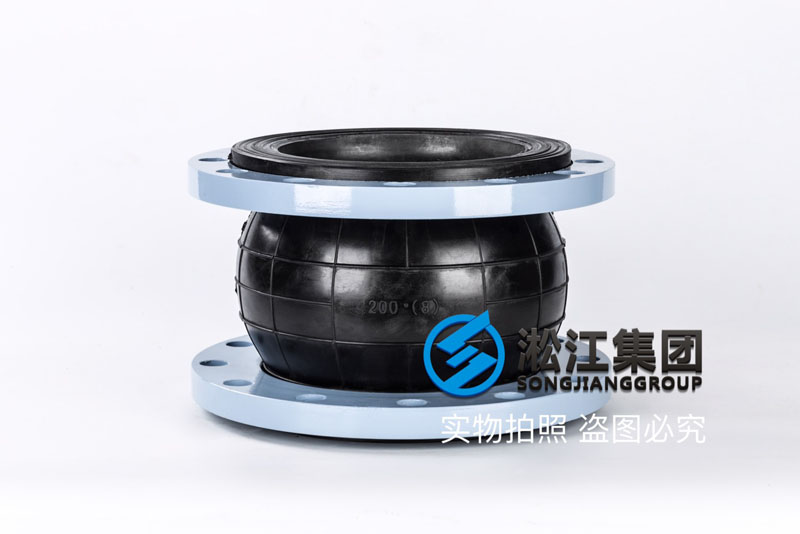

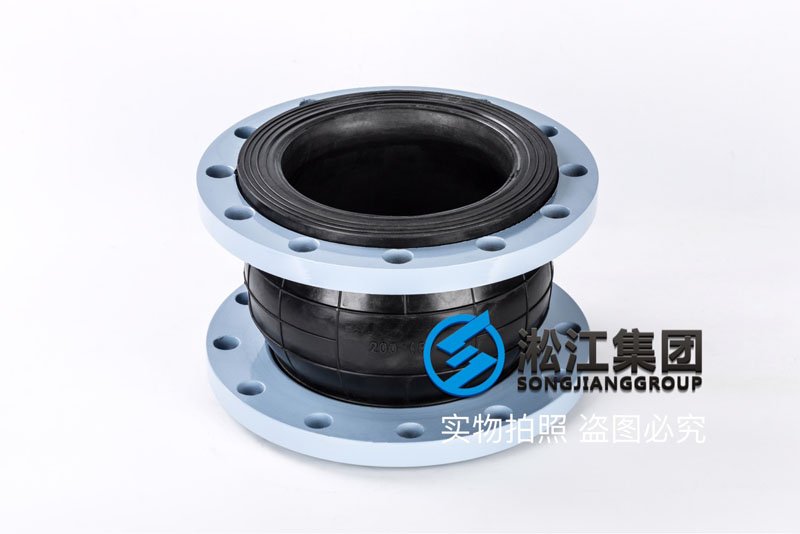

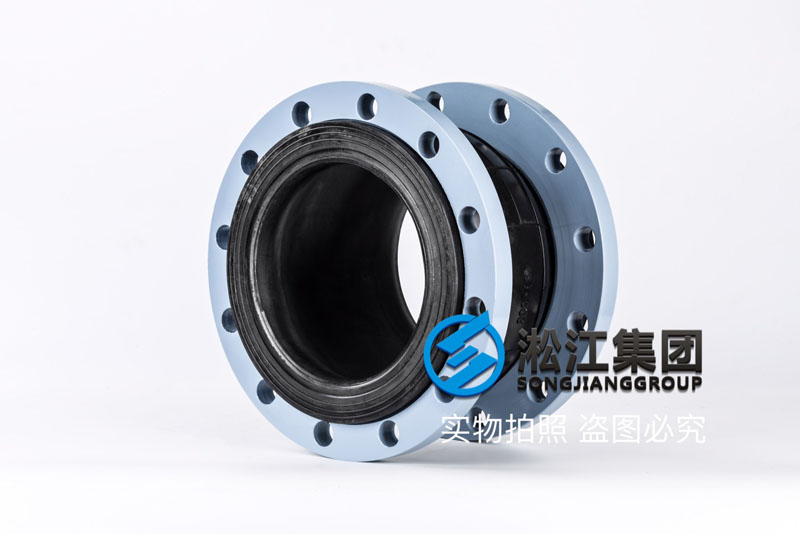

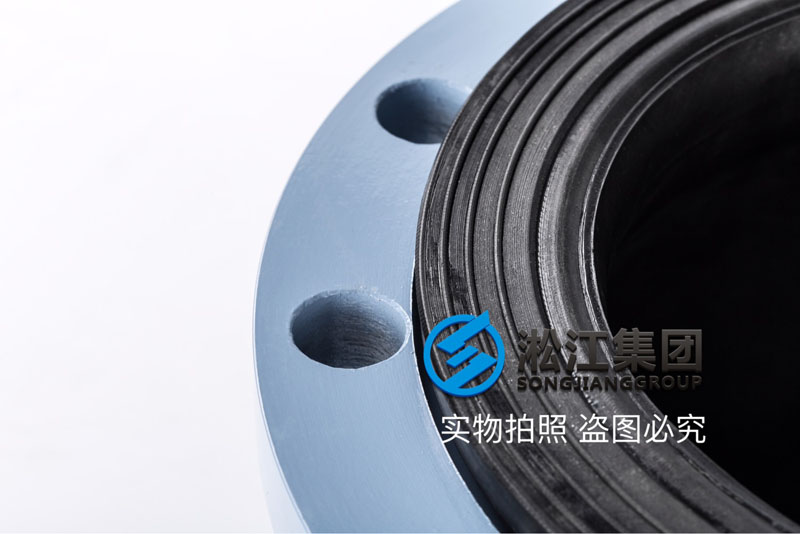

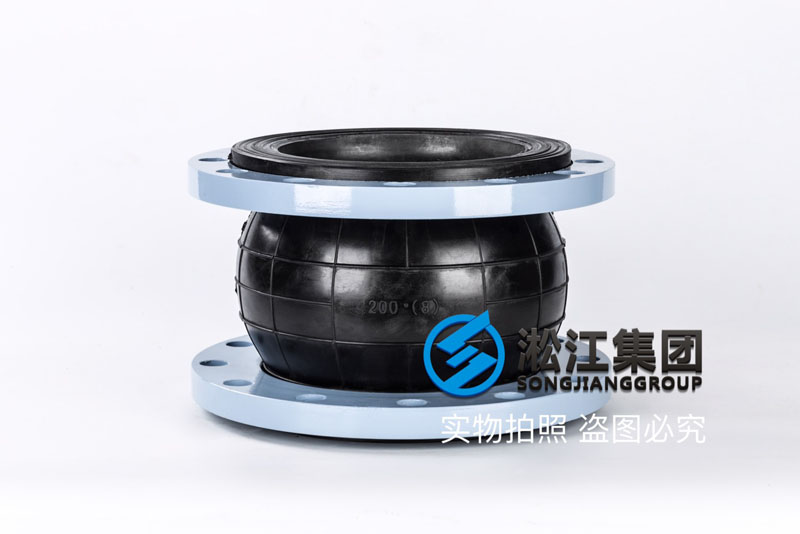

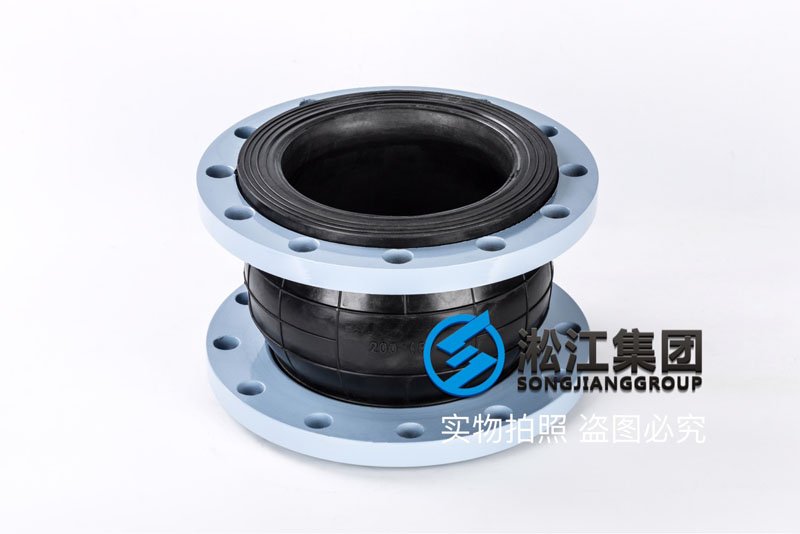

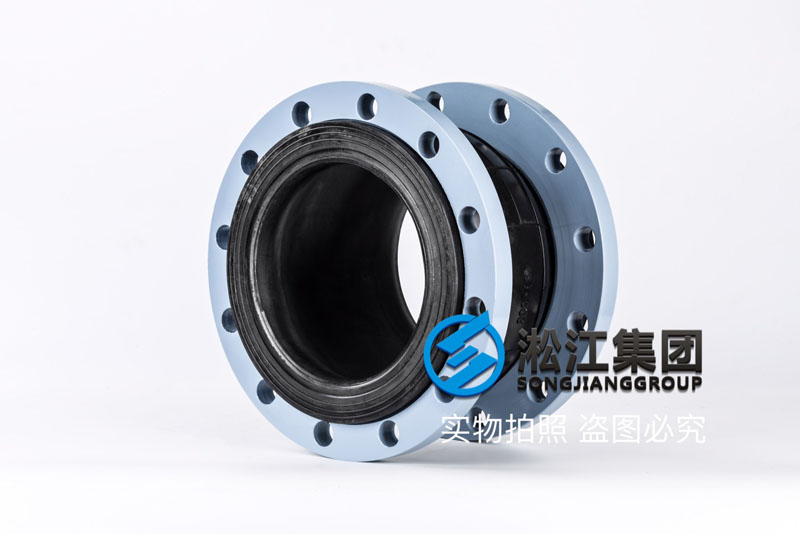

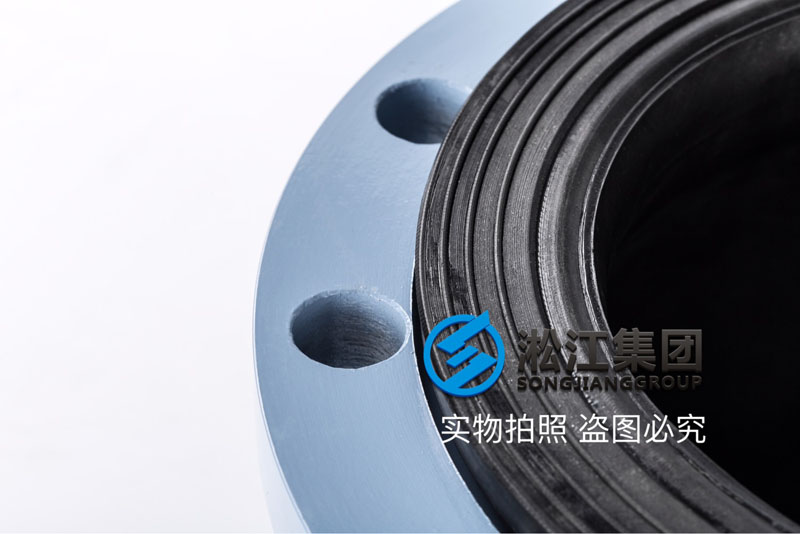

銆怬EM銆慏N200鍠悆姗¤啝鎺ラ牠浠e姞宸モ€滆嚜鍕曞寲鐢熺敘淇濊唱淇濋噺鈥�

[OEM] DN200 single ball rubber joint for processing "automatic production quality and quantity".

涓婃捣娣炴睙娓涢渿鍣ㄩ泦鍦樻湁闄愬叕鍙稿畼鏂圭恫绔欑偤鎮ㄤ粙绱癸細銆怬EM銆慏N200鍠悆姗¤啝鎺ラ牠浠e姞宸モ€滆嚜鍕曞寲鐢熺敘淇濊唱淇濋噺鈥濅俊鎭紝娣炴睙闆嗗湗鏄湅鍏ф鑶犳帴闋妤€氶亷鑷嫊鍖栫敓鐢㈢殑浼佹キ锛岃嚜鍕曞寲鐨勭敓鐢㈢⒑淇濅簡鐢㈠搧鐨勮唱閲忓拰鐢熺敘鐢㈣兘锛屼互涓嬫槸瑭崇窗浠嬬垂銆�

Shanghai Songjiang shock absorber Group Co., Ltd. official website for you: [OEM] DN200 single ball rubber joint replacement processing "automation production quality assurance" information, Songjiang group is the domestic rubber joint industry through automated production enterprises, automated production to ensure the quality of the product and production capacity, the following is the detailed introduction Shao.

浠e伐璨肩墝瑾槑锛�

鎴戝粻鏈変竴濂楃劇妯欑(鍏凤紝鐐洪枼闁€寤犳彁渚涜布鐗屾湇鍕欙紝涓昏鍨嬭櫉鍖呮嫭锛欴N40~DN400锛屽鍔�1.6Mpa锛岃捣瑷傞噺锛�100鑷轰互涓婏紝涓€鑸櫘閫氶亷姘寸殑鎴戝粻閮芥湁鐝捐波锛屽鏋滈渶瑕佺壒娈婃潗璩殑闇€瑕佸畾鍋氾紝渚嬪鐒℃涓夊厓涔欎笝姗¤啝灏遍渶瑕佸畾鍋氾紝璧疯▊閲忥細姣忕ó鍨嬭櫉100鑷轰互涓婏紝鍛ㄦ湡30澶┿€�

The OEM sign says:

Our factory has a set of non - standard abrasive tools, professional for the valve factory to provide OEM service, the main models include: DN40~DN400, pressure 1.6Mpa, starting the quantity: more than 100 units, ordinary ordinary water in our factory all have spot, if the need for special material needs to be customized, such as non - standard ethylene propylene rubber will need to be customized, the quantity: each type: each type The number is over 100, and the cycle is 30 days.

鐐轰粈涔堥伕鎿囨窞姹熼泦鍦橈紵

娣炴睙闆嗗湗鏄湅鍏ф鑶犳帴闋妤搧鏈夎嚜宸辩殑鏂板瀷鑷嫊鍖栫敓鐢㈠伐寤狅紝鎿佹湁鑷繁鐨勮唱閲忕鎺ч珨绯伙紝鐪嬬湅鎴戝€戞槸濡備綍灞ゅ堡鎶婃帶姗¤啝鎺ラ牠鐨勭敓鐢㈡祦绋嬬殑锛�

閲囪臣鎸囧畾鍝佺墝鍘熸潗鏂�-姣忔壒娆″師鏉愭枡鍏ュ韩鍓嶅寲椹�-鍒朵綔瑭︾墖娓│-姗¤啝閰嶆柟鑷嫊閰嶆枡-鑷嫊閫叉枡-鑷嫊娣风厜-鑷嫊闁嬬厜-鑷嫊瑁佸壀-鑷嫊鎴愬瀷-鑷嫊纭寲-鍙姗熷櫒浜虹~鍖栫己闄锋娓�-姘村妾㈡脯-鎬ц兘妾㈡脯-鐤插嫗瑭﹂-鏅鸿兘鍊夊韩-鍖呰-鐧艰波銆�

閫欎竴绯诲垪鐨勮唱閲忔妸鎺ф祦绋嬶紝鍜岃嚜鍕曞寲鐨勭敓鐢㈣ō鍌欙紝璁撴姊板寲渚嗘妸鎺х敘鍝佽唱閲忥紝璁撲汉鐐虹殑澶辫闄嶄綆鐐洪浂锛岃畵鍑哄粻鐨勬瘡涓€鑷烘鑶犳帴闋悎鏍硷紝骞朵笖鎴戝粻姗¤啝鎺ラ牠閫氶亷鍦嬪鍨嬪紡瑭﹂锛岀嵅寰楀湅瀹跺瀷寮忚│椹楀牨鍛婏紝鍦ㄦ鑶犳帴闋牁鍩燂紝鎴戝€戞槸瑾嶇湡鐨勩€�

Why do you choose Songjiang group?

Songjiang group is a new automatic production plant owned by the rubber joint industry in China. It has its own quality control system. See how we manage the production process of rubber joint. Feeding - automatic mixing - automatic opening - Automatic tailoring - automatic molding - Automatic vulcanization - Visual Robot vulcanization defect detection - water pressure testing - performance testing - fatigue tests - warehousing packaging - delivery, this series of quality control processes, and automated production equipment, mechanized to control product quality and reduce human error to Zero, let the factory every rubber joint qualified, and Songjiang group is the domestic rubber joint industry through the TS pressure pipe production license unit, TS number: TS2731B90-2020, and my factory rubber joint through the national type test, the national type test certificate, in the field of rubber joint, we are professional.

鍠悆姗¤啝鎺ラ牠浠e姞宸ュ粻浠嬬垂锛�